What is a Hydrophilic Coating?

Hydrophilic coatings are used in medical devices to reduce surface friction while increasing lubricity so that a medical device can reach its intended destination as easily as possible.

Hydrophilic is the chemical term for “water-loving.” From a chemical standpoint, this means the coating will participate in dynamic hydrogen bonding with surrounding water. Hydrophilic coatings are also ionic and usually negatively charged, which further facilitates aqueous interactions. Physically, these chemical interactions with water give rise to hydrogel materials that may exhibit extremely low coefficients of friction. Taken together, such chemical and physical characteristics describe a class of materials that are wettable, lubricious, and suitable for tailored biological interaction

What is Lubricity?

Lubricity, as it relates to hydrophilic coatings, is the measure of the reduction in friction and/or wear by a lubricant. In non-scientific terms, it can be thought of as “slipperiness.”

What types of coating processes does Biocoat offer?

Biocoat offers several methods to apply the coating to the substrate. These methods include:

Dip Coating

When devices are dip-coated, they are lowered into individual solution tubes to dip them in the coating. There are generally five steps to dip coating:

- Surface preparation/washing

- Submersion of the device in a coating liquid

- Withdrawal from the coating liquid

- Drying and/or curing of the coating (via heat or UV)

- Post processing, if required

Film Coating

The process of coating film materials, like breast implant funnels, allows for different flat substrate materials to be hydrophilicly coated.

Fill and Drain Coating

Fill and drain coating consists of the substrate material being filled with the coating solution and then drained to begin the cure process. This is most often used for coating the inner diameter (ID) applications.

What are Contract Coating Services?

Some hydrophilic coating providers, like Biocoat, offer Contract Coating Services to apply the coating to your device at their facility. The benefit of using Biocoat’s Contract Coating Services is the ability to ensure that your products will be expertly coated for maximum safety, maneuverability and patient comfort. Using Contract Coating Services saves device companies the time, cost and equipment investments required to complete the coating process in-house.

What is a Pinch Test?

Pinch testing is the most common test for identifying friction of a surface on a medical device. This test involves pinching a catheter, wire, or surface (test article) between two plates with a known amount of force, while using a servo motor to pull the test article through the plates. A mechanical analyzer measures the force it takes to pull the device through.

How are Biocoat’s coatings cured?

Biocoat is one of the only hydrophilic coating providers to offer industry-leading performance for both thermal and ultraviolet cured technologies.

Thermal Heat Cure

In a thermal heat cure system, coated items are placed in an oven for a certain amount of time. Thermal curing ensures that coatings are dried equally, as the heat source is non-directional. Some advantages of the thermal cure process are the abilities to coat the inner diameter of substrate materials and to coat large amounts of materials in one cycle.

Ultraviolet (UV) Cure

In a UV cure system, the coated items are placed in a chamber of UV lights that rotates either itself or the material to ensure that the coating dries evenly. UV cure timelines are typically faster than a thermal cure system.

What are Particulates?

In the context of medical devices, “particulates” are foreign materials left behind by a device. When a device is deployed or exposed to the patient, particles may be released and become lodged in the patient’s vascular capillary system. Whether this is harmful to the patient depends on the size, shape, and composition of the particles, as well as where and to what degree they cause an occlusion, or blockage. The source of these particulates may be the manufacturing process and environment, product packaging, or the device itself.

What type of devices do you coat?

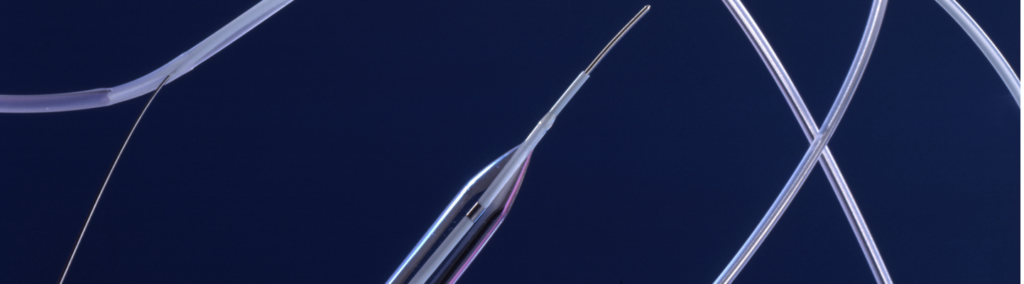

Neurovascular

Neurovascular medical devices are required to quickly and effectively treat strokes. Examples of neurovascular devices that may require a hydrophilic coating include thrombectomy devices, micro-catheters, micro-guidewires, coil delivery systems, flow diversion devices and arterial stents.

Cardiovascular

Cardiovascular devices are designed to diagnose and treat heart rhythm disorders and other related health problems. Examples of cardiovascular devices that may require a hydrophilic coating include PTCA catheters, guiding catheters, guidewires, stent delivery systems, introducer sheaths and CTO crossing catheters.

Peripheral Vascular

Peripheral vascular devices are used to treat peripheral vascular diseases, which are slow and progressive blood circulation disorders. Examples of peripheral vascular devices that may require a hydrophilic coating include CTO devices, atherectomy systems, balloon dilation catheters, peripheral imaging catheters and guidewires.

Ophthalmic

Ophthalmology devices are primarily used for treating various eye conditions and infections. Examples of ophthalmic devices that may require a hydrophilic coating include IOL cartridges, surgical needles and injectors.

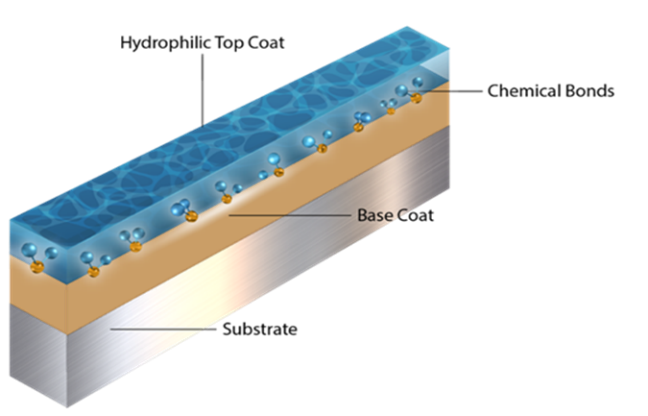

How are Biocoat’s HYDAK coatings applied to the substrate materials?

HYDAK® is Biocoat’s proprietary hydrophilic coating solution, available in thermal heat cure and UV light cure. HYDAK hydrophilic coating technology offers industry-leading performance in the three criteria (lubricity, durability and particulates) that measure coating effectiveness.

HYDAK coatings are applied using a basecoat and a topcoat. Our basecoat is hydrophobic and is used to normalize the substrate material (click here for all materials we coat) and to prepare the surface for the application of the hydrophilic topcoat. Our topcoat provides a lubricious “slippery” surface on the medical device, which allows the device to easily move through the body. The base coat and topcoat covalently bond, creating higher durability and minimal particulate counts.