Your One-Stop Solution For Custom Made Polymers

Chempilots brings your idea of a new polymer into product delivery at low or final scale custom polymer synthesis to support your further development.

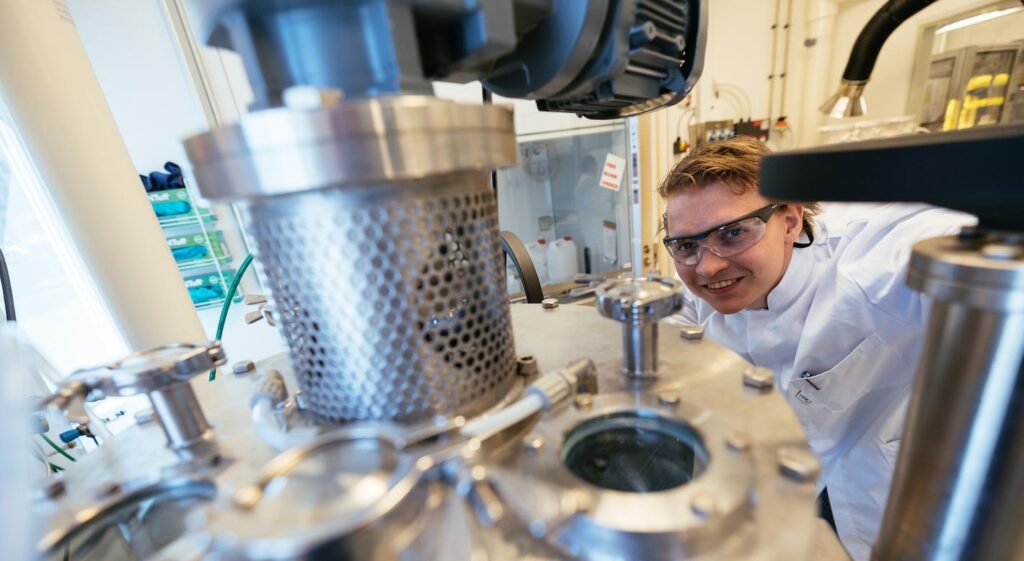

Through processing research and testing we define the critical parameters required for the creation of your polymer. From here, scale-up can occur safely, ensuring the integrity of your polymer.

From initial processing to final inspection and product release Chempilots handle clean-room operations of your specialty polymer product and deliver for new commercial use or as a second source of supply.

Do you have an idea for a specialty polymer that requires experts in chemical synthesis, analysis and manufacturing? Using our experience, we can help you develop a polymer for your specific needs.

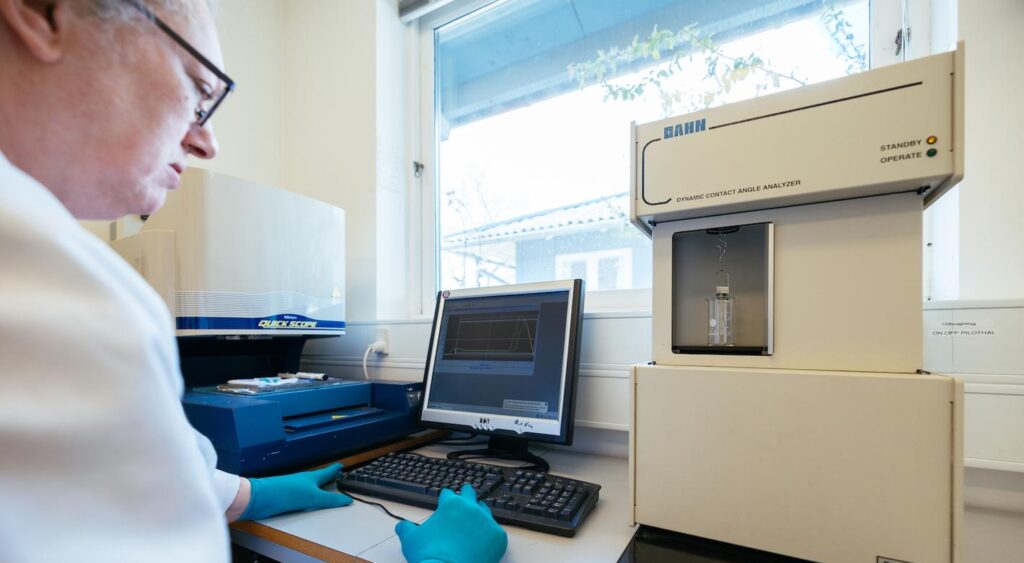

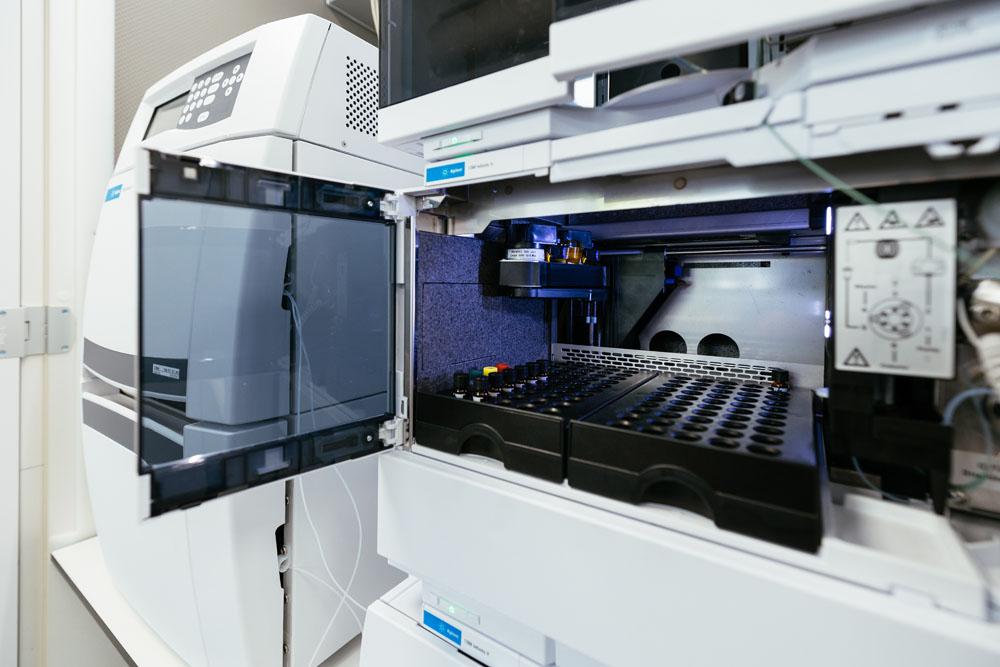

During our research, we conduct polymer analysis to help targeting and strengthening your polymer performance. At Chempilots, we ensure the polymer we create is suitable for the conditions of your application.

Our fully-equipped facility boasts 27,500 square-feet of lab space to support from initial research to final polymer production, the Chempilots facilities and dedicated team offer the state-of-the-art equipment and service required to do it all.

Biocompatible polymers are widely used in medical devices due to their compatibility with the human body. A mix of natural and synthetic, these polymers enable life-saving technology such as pacemakers and can be critical in the treatment of medical conditions

Biodegradable polymers are used for diverse applications. They must also be engineered correctly to breakdown after their intended purpose. Chempilots has developed various types of polymers for numerous applications such as surgical sutures, medical implants, tissue regeneration and nanotechnology.

Polymers are used widely in the biomedical field with attainable properties such as being non-toxic, lightweight, flexible, durable and biodegradable. With over 60 years of experience, Chempilots is ready to assist with your biomedical polymer needs. Our dedication to quality ensures that we’ll deliver the safest and most highly functionalized product for your needs.

Degradable biocompatible polymers exist to improve drug delivery. Biocompatible polymers feature both natural and synthetic (man-made) materials, including materials that enable degradation over time

We specialize in developing polymers for drug delivery applications, including those used for slow-dose release (extended-release) drugs. Polymers in this family include microparticles, micelles, polyplexes, drug conjugates, implants and other examples. Our capabilities ensure your polymer meets critical drug requirements such as release period and permeation.

Durable and degradable hydrogels are used in a variety of applications, including contact lenses, cell encapsulation and even in creams and lotions. These hydrogels can either degrade over time or remain durable, based on your application’s requirements.

Wetting agents are used to reduce surface tension so a liquid or solid can easily spread. These polymers are found in hydrogels and poly-HEMA applications, which are often used for medical devices such as contact lenses and urology catheters.

Medical devices require polymers for highly specific functions. From 3D print structures to thermoplastics and adhesives to biodegradable, Chempilots develops high-quality custom polymers to fit your specific application.

Pharmaceutical polymers must meet all processability, stability and therapeutic response requirements. Chempilots has years of expertise in helping companies develop specialty polymers to meet critical release profiles.

Chempilots also develops polymers found in cosmetics such as hyaluronic acid, which is commonly found in anti-aging products. Cosmetic polymers are also used as thickeners, structing agents and delivery agents for antixidants.

Our team of engineers and polymer experts would be glad to have a discussion about your project and its requirements.

The latest news, articles, and resources, sent to your inbox.