Our hydrophilic coatings provide best-in-class performance with the industry’s lowest particulate counts. Our flexible service model allows you to coat your materials at your production facility or our Contract Coating Services Unit. Your medical device is specifically designed to achieve its intended goal, and our coatings enable your device to perform at the highest level, while maintaining the durability expected for reliable procedures.

At Biocoat, we are focused on researching, developing, manufacturing, and applying the best coatings in the market. By becoming an extension of your team, we are fully dedicated to providing you with a best-in-class experience at every stage of your product’s development and commercial lifecycle.

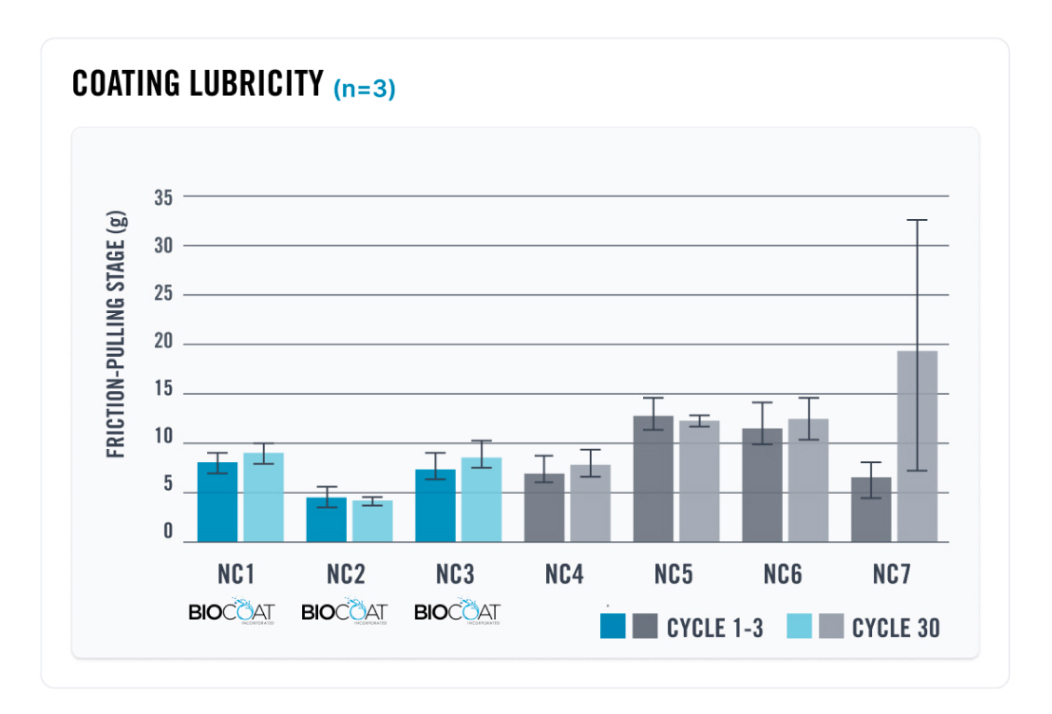

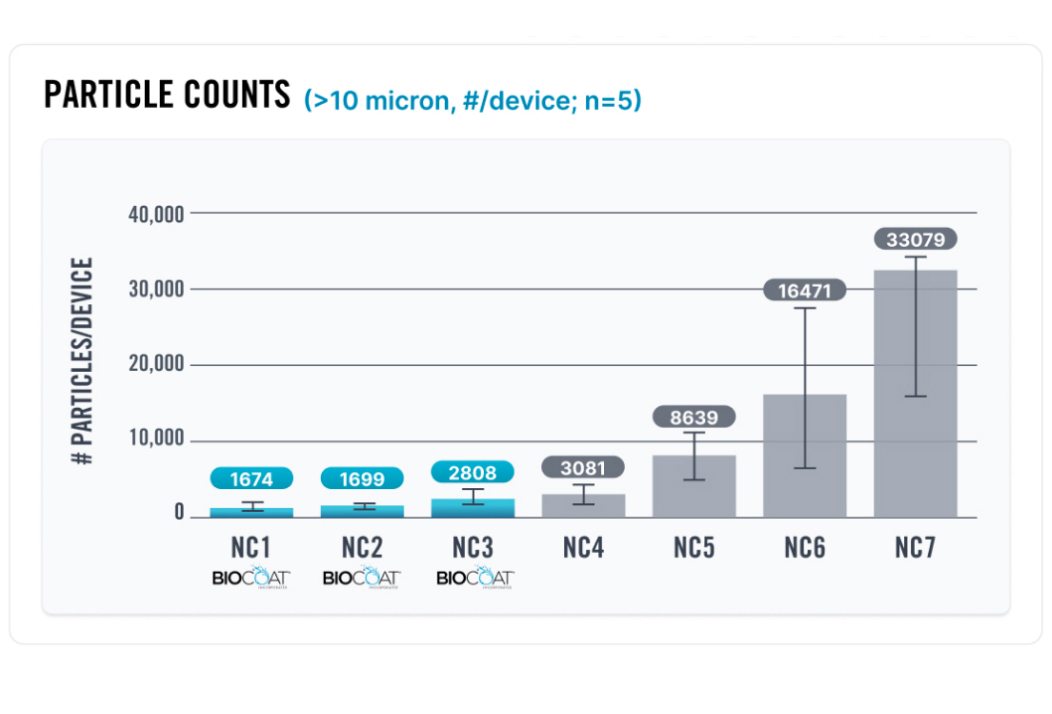

The following charts show the results of a series of tests that the Biocoat Research & Development team completed to test the friction, durability, and particulates on commercially available medical devices. Microcatheters were used for this comparison, as their length and flexibility allow for a robust assessment of lubricity and durability.

In this chart, the Biocoat R&D team purchased seven (7) different commercially available products, three (3) of which were coated with Biocoat’s HYDAK® technology. The Biocoat team measured both the lubricity and durability of each of the microcatheters in an effort to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® exhibits best-in-class lubricity and durability results.

In this chart, the Biocoat R&D team purchased seven (7) different commercially available products, three (3) of which were coated with Biocoat’s HYDAK® technology. The Biocoat team measured the number of particulates generated from each of the catheters to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® exhibits best-in-class results for low particulates.

The customer was looking for a hydrophilic coating to improve both implantation and explantation performance for a new ophthalmic bioelectronic device.

Our team was faced with the challenge of developing a coating formulation and application method for a very small device (<1.5 cm in length) that required specialized fixturing and masking methods. Further, the device materials consisted of both exotic polymeric and metallic materials, which required advanced surface preparation techniques and coating selection.

Biocoat’s Application Development Team partnered with the customer to help design custom fixturing and develop the masking process. Our team used selected our HYDAK® UV coating , which integrates well with delicate heat sensitive substrates. An advanced plasma treatment step was then incorporated to further improve overall performance. The device is currently undergoing human trials in support of FDA clearance.

Medical Device Company

Medical Device CompanyOur team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

A major portion of Biocoat’s success has been attributed to our commitment to delivering a high-touch customer service experience. Our coating experts are ready to assist you with the development of a coating that is specifically designed to match your project’s requirements.

By utilizing Biocoat’s Contract Coating Services offering, you are free to focus on device innovation, design, and assembly, without the need to incorporate complex and coating processes into your manufacturing lines. Our best-in-class customer service, world class coating equipment, process controls, and rapid turnaround times are a commonly selected option to give you peace of mind that your device’s hydrophilic coating application is taking care of by experts.

The latest news, articles, and resources, sent to your inbox.