Our hydrophilic coatings provide best-in-class performance with the industry’s lowest particulate counts. Our flexible service model allows you to coat your materials at your production facility or our Contract Coating Services Unit. Your medical device is specifically designed to achieve its intended goal, and our coatings enable your device to perform at the highest level, while maintaining the durability expected for reliable procedures.

At Biocoat, we are focused on researching, developing, manufacturing, and applying the best coatings in the market. By becoming an extension of your team, we are fully dedicated to providing you with a best-in-class experience at every stage of your product’s development and commercial lifecycle.

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

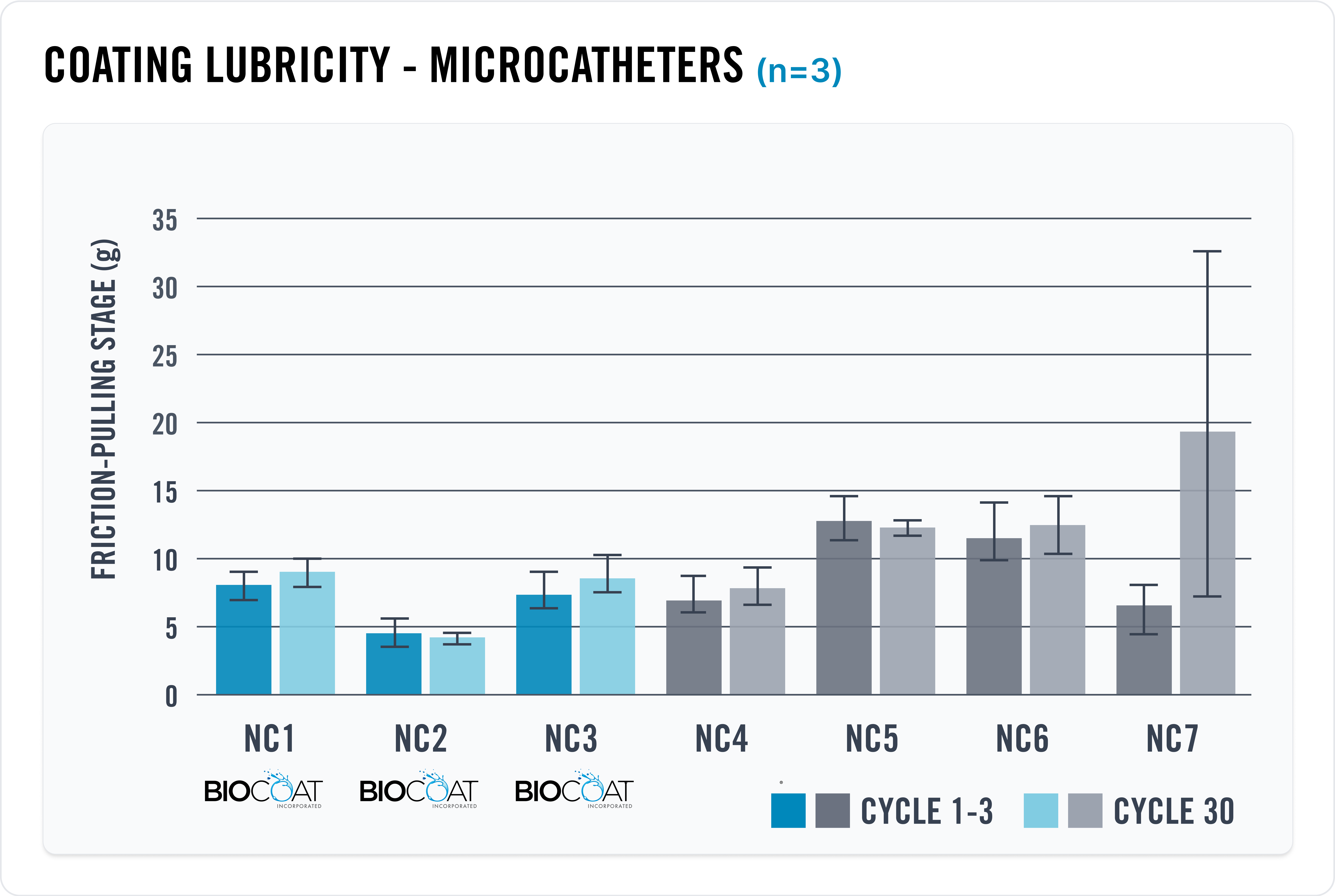

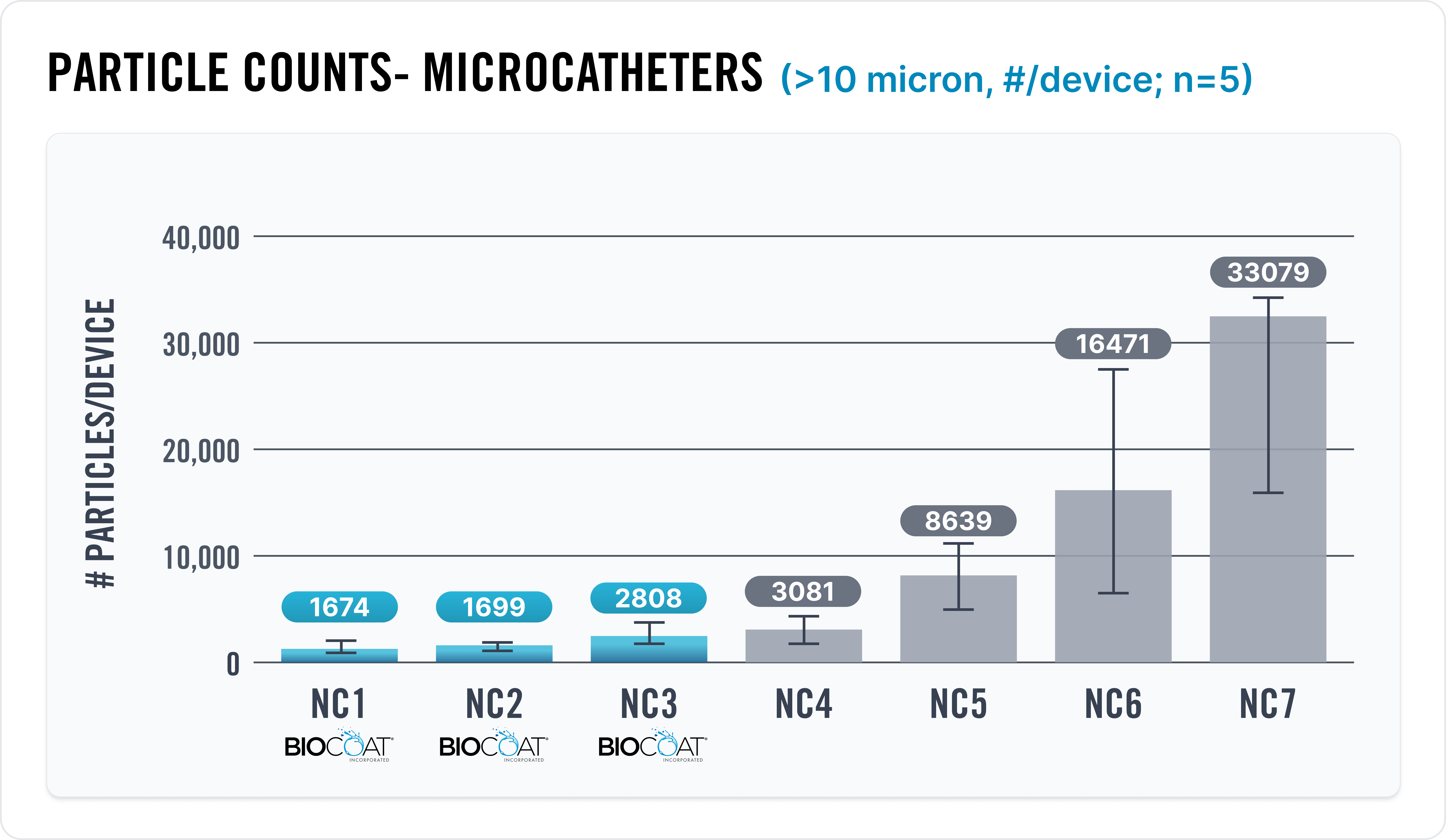

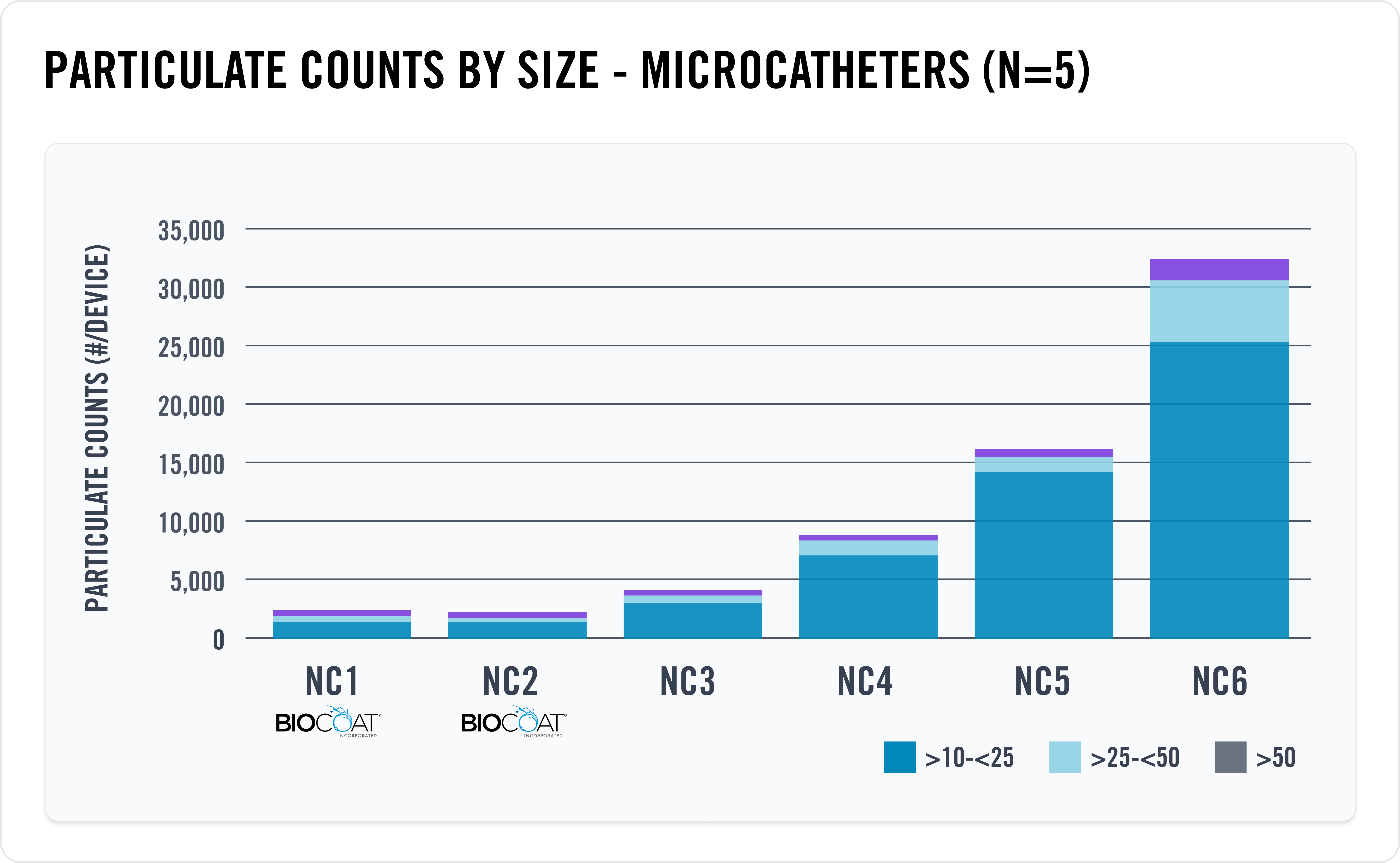

At Biocoat, our HYDAK® coatings offer best-in-class performance in lubricity, durability, and particulates. Our coatings give you a choice to cure the coatings using either heat or Ultraviolet (UV) light. The following charts show the results of a series of tests that the Biocoat Research & Development team completed to test the friction, durability, and particulates on commercially available microcatheters to evaluate how our coatings perform compared to other coatings on the market.

In this chart, the Biocoat R&D team purchased seven (7) different commercially available neurovascular microcatheters, three (3) of which were coated with Biocoat’s HYDAK® technology. The Biocoat team measured both the lubricity and durability of each of the microcatheters in an effort to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® exhibits best-in-class lubricity and durability results.

In this chart, the Biocoat R&D team analyzed the results generated from six (6) different commercially available neurovascular microcatheters, two (2) of which were coated with Biocoat’s HYDAK® technology. The Biocoat team measured the number and overall size of each of the particulates generated from the catheters to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® generates the lowest number of particulates in the tested devices.

In order for our coatings to retain their best-in-class status, we continually test our products to ensure that they meet the three criteria on which hydrophilic coatings are measured. An effective lubricious coating should have each of the following components:

Our customer required a coating that allowed the device to reach further into the vasculature while including the use of a soft distal tip.

Biocoat was required to supply a coating that would be extremely durable, while ensuring optimal performance for maneuverability through the torturous paths in the neurovascular anatomy.

Biocoat’s Application Development team recommended HYDAK® Thermal coatings to the client’s Engineering team to develop a custom coating solution that allowed maximum lubricity, durability and to meet the FDA’s requirements for particulate counts. The client’s device was FDA 510k cleared for use and has become the leading neurovascular catheter on the market.

Neurovascular Medical Device Company

Neurovascular Medical Device Company Our team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

A major portion of Biocoat’s success has been attributed to our commitment to delivering a high-touch customer service experience. Our coating experts are ready to assist you with the development of a coating that is specifically designed to match your project’s requirements.

If you plan to coat the devices at your facility, we support you through the same best-in-class customer support and world-class coating manufacturing operations. We’re committed to delivering your coating materials on time, and as expected, every time. Our online ordering system is backed by a live Customer Support team, who are eager to assist with any questions or support you may require.

The latest news, articles, and resources, sent to your inbox.