CARDIOVASCULAR COATING SOLUTIONS

Custom Coatings Designed for Cardiovascular Devices

Our hydrophilic coatings provide best-in-class performance with the industry’s lowest particulate counts. Our flexible service model allows you to coat your materials at your production facility or our Contract Coating Services Unit. Your medical device is specifically designed to achieve its intended goal, and our coatings allow your device to be easily maneuverable and highly durable to optimize vascular access and minimize procedure time.

At Biocoat, we are focused on researching, developing, manufacturing, and applying the best coatings in the market. By becoming an extension of your team, we are fully dedicated to providing you with a best-in-class experience at every stage of your product’s development and commercial lifecycle.

TYPES OF CARDIOVASCULAR DEVICES UTILIZING HYDROPHILIC COATINGS

- PTCA Balloon Catheters

- PTA Balloon Catheters

- PTCA Dilatation Catheters

- Diagnostic Catheters

- Aspiration Catheters

- Stent Delivery Systems

- Guiding Catheters

- Guidewires

- Introducer Sheaths

- Coronary Atherectomy Devices

- AAA Stent Graft Systems

- CTO Crossing Catheters

- IVUS Catheters

- Transcatheter Heart Valve Replacement Systems

- Steerable Guide Catheters

- AND MANY MORE…

At Biocoat, we offer a complete solution for coating cardiovascular medical devices.

OUR SERVICES PROCESS

Substrates We Coat

Polymerics

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

- Nylon/Polyamide

- PEBAX

- Polyurethane

- PEEK

- Chronoprene

- Tecothane

- Tecoflex

- Aesno

- Polypropylene

- Polyethylene

- Hydrophilic films

- Silicone

- AND MANY MORE…

Metals

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

- Stainless Steel

- Nitinol

- Platinum

- Gold

- Nickel

- Titanium

BEST-IN-CLASS PERFORMANCE

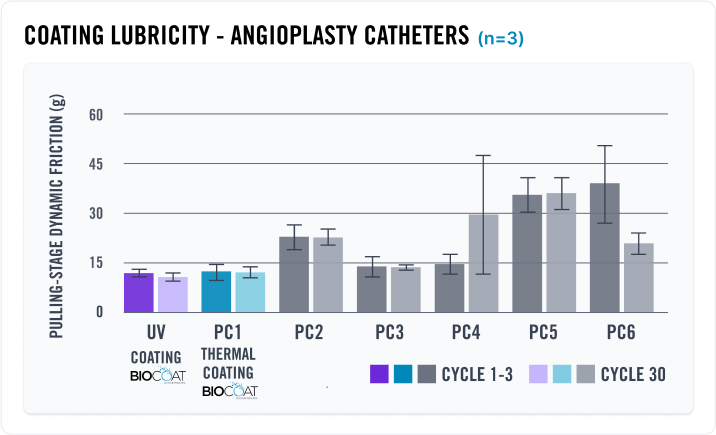

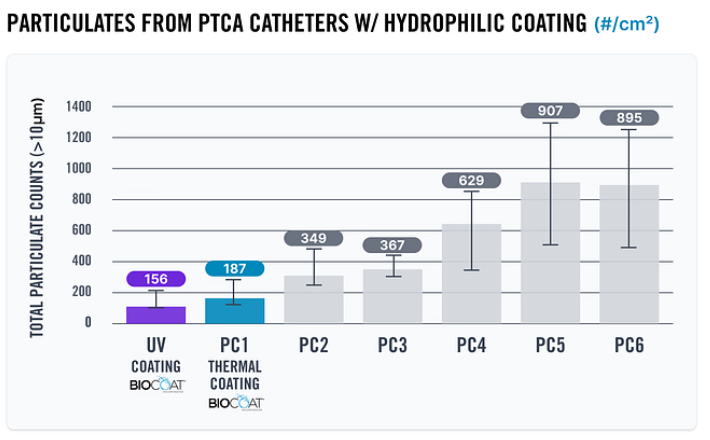

At Biocoat, our HYDAK® coatings offer best-in-class performance in lubricity, durability, and particulates. Our coatings give you a choice to cure the coatings using either Thermal heat or Ultraviolet (UV) light. The following charts show the results of a series of tests that the Biocoat Research & Development team completed to test the friction, durability, and particulates on commercially available microcatheters to see how our coatings perform compared to other coatings on the market.

In this chart, the Biocoat R&D team purchased six (6) different commercially available angioplasty catheters, one (1) coated with Biocoat’s HYDAK® Thermal technology. The chart also shows Biocoat’s HYDAK® UV coating performance compared to the six (6) commercially available microcatheters. Biocoat team measured both the lubricity and durability of each catheter to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® exhibits best-in class lubricity and durability results

In this chart, the Biocoat R&D team tested six (6) commercially available 510K cleared devices. The Biocoat team measured particulate counts of our Biocoat HYDAK® UV and Thermal coatings to compare them in relation to industry competitors. The results show that the Biocoat UV and Thermal coatings provide significantly lower particulate counts than the competition

Interested in a Hydrophilic Coating Solution for your Cardiovascular Devices?

Our team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

Dedicated Support Throughout Your Project Development

A major portion of Biocoat’’s success has been offering a high-touch customer service experience. Our coating experts are ready to assist you with the development of a coating specifically designed to match your project’s requirements.

A STANDARD ENGAGEMENT WITH BIOCOAT:

-

Contract Coating ServicesBy utilizing Biocoat’s Contract Coating Services offering, you are free to focus on device innovation, design, and assembly, without the need to incorporate complex and coating processes into your manufacturing lines. Our best-in-class customer service, world class coating equipment, process controls, and rapid turnaround times are a commonly selected option to give you peace of mind that your device’s hydrophilic coating application is taking care of by experts.

-

Reagent FulfillmentIf you plan to coat the devices at your facility, we support you through the same best-in-class customer support and world-class coating manufacturing operations. We’re committed to delivering your coating materials on time, and as expected, every time. Our online ordering system is backed by a live Customer Support team, who are eager to assist with any questions or support you may require.