Our hydrophilic coatings provide best-in-class performance with the industry’s lowest particulate counts. Our flexible service model allows you to coat your materials at your production facility or our Contract Coating Services Unit. Your medical device is specifically designed to achieve its intended goal, and our coatings enable your device to perform at the highest level, while maintaining the durability expected for reliable procedures.

At Biocoat, we are focused on researching, developing, manufacturing, and applying the best coatings in the market. By becoming an extension of your team, we are fully dedicated to providing you with a best-in class experience at every stage of your product’s development and commercial lifecycle.

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

Our coatings can be applied to almost all substrate materials used in Cardiovascular catheter designs. Our unique coating methods have been successfully used in many applications where other options did not meet the design criteria.

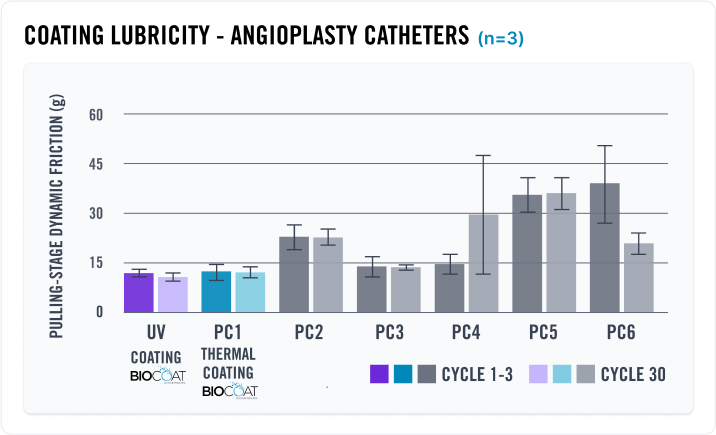

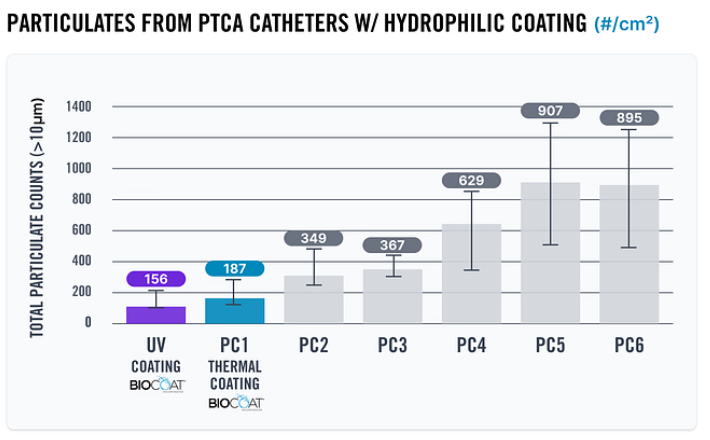

At Biocoat, our HYDAK coatings offer best-in-class performance in lubricity, durability, and particulates. Our coatings give you a choice to cure the coatings using either Thermal heat or Ultraviolet (UV) light. The following charts show the results of a series of tests that the Biocoat Research & Development team completed to test the friction, durability, and particulates on commercially available microcatheters to see how our coatings perform compared to other coatings on the market.

In this chart, the Biocoat R&D team purchased six (6) different commercially available angioplasty catheters, one (1) coated with Biocoat’s HYDAK® Thermal technology. The chart. The chart also shows Biocoat’s HYDAK® UV coating performance compared to the six (6) commercially available microcatheters. Biocoat team measured both the lubricity and durability of each catheter to determine where HYDAK® stands in relation to industry competitors. Our testing proves that HYDAK® exhibits best-in class lubricity and durability results

In this chart, the Biocoat R&D team tested six (6) commercially available 510K cleared devices. The Biocoat team measured particulate counts of our Biocoat HYDAK® UV and Thermal coatings to compare them in relation to industry competitors. The results show that the Biocoat UV and Thermal coatings provide significantly lower particle counts than the competition

To successfully complete the project design, the developing company’s engineering team required a high-performing hydrophilic coating and to implement production techniques to match the high volume and high-efficiency production requirements during the introduction of a family of balloon catheters.

Biocoat was asked to develop a coating that would perform on each catheter being planned for the product portfolio. Each catheter had different coating requirements, including different coating lengths, lubricity requirements, masking and performance standards. One particularly challenging area was the development of a solution and process to mask the balloons on the catheters so that the coating did not interfere with the performance of the balloon.

Biocoat worked closely with the engineering team on each project to develop a coating to maximize the overall device performance. Biocoat also designed and assisted with developing production techniques that would allow for large volumes of product to be coated efficiently and effectively. Each product has been US-FDA approved and is available in several countries including the United States, Middle East, the Asia-Pacific region, Australia, Latin America, and Africa.

Medical Device Executive and Serial Entrepreneur

Medical Device Executive and Serial Entrepreneur Our team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

A major portion of Biocoat’’s success has been offering a high-touch customer service experience. Our coating experts are ready to assist you with the development of a coating specifically designed to match your project’s requirements.

The latest news, articles, and resources, sent to your inbox.