Biocoat Announces Formation of Surmodics Services & Technologies Division Following Acquisition and Divestiture Transactions.

Discover the ultimate solution for coating metal substrates with Biocoat’s HYDAK® hydrophilic coatings, engineered to deliver unparalleled performance on challenging metal substrates commonly used in medical devices. Our HYDAK® technology offers a PFAS and PTFE free option to increase the lubricity of devices such as guidewires and is engineered to maximize coating efficiency. This enables a seamless application process that allows you to apply directly to metal substrates without an additional tie coat layer, yielding significant time and material cost savings. With this innovative approach, you’ll benefit from an efficient production line that requires fewer materials and allows for a thinner, yet robust coating while eliminating PFAS from your device. High performance is no longer an option; it’s a standard with Biocoat’s hydrophilic coatings, designed to enhance the performance of your medical device.

Biocoat’s HYDAK® hydrophilic coatings provide the fastest and most efficient process for coating metal substrates. Applying directly to metal substrates eliminates the time needed to apply and cure a primer, or tie layer, resulting in faster production with fewer steps.

The HYDAK® metal coating process utilizes the identical materials that are used for coating polymeric substrates. By removing the tie layer, also known as the primer, you can reduce material expenses and minimize the amount of materials needed for storage.

As supply chain and regulatory pressures increase the need to move away from PFAS, HYDAK® hydrophilic coatings provide a high-performance PFAS-free option for your device. This allows you to remove PTFE and PFAS from your metal substrate without sacrificing performance.

HYDAK® coatings provide equivalent or better performance in lubricity, durability, and particulate counts versus polymer cladding or other hydrophilic coatings.

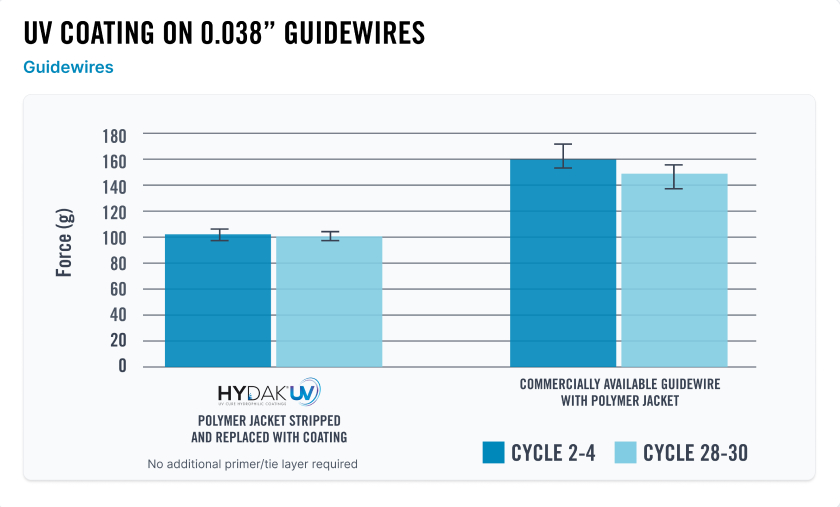

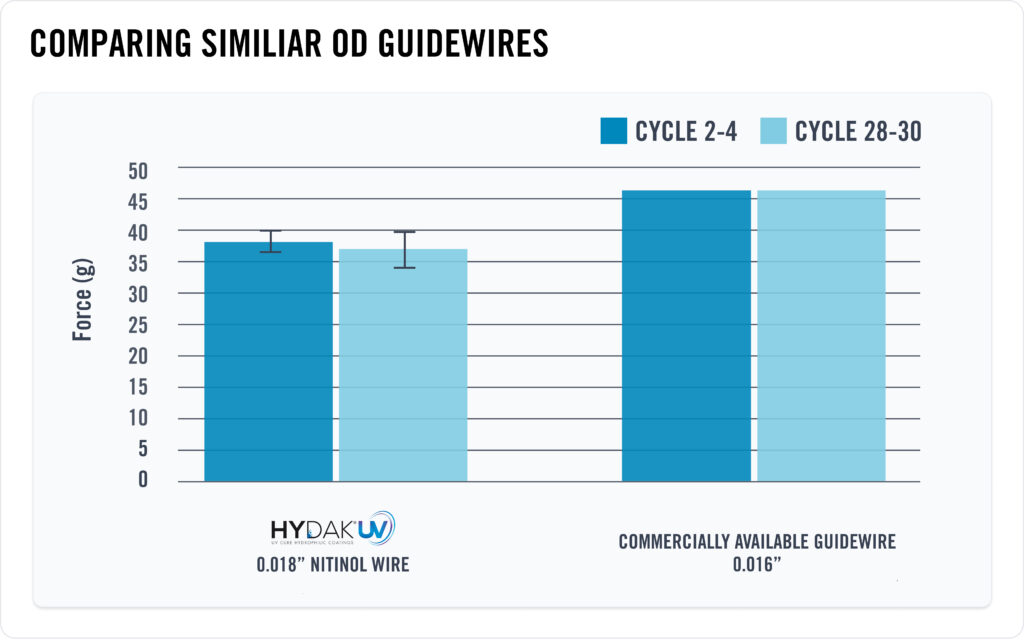

At Biocoat, our HYDAK® coatings offer best-in-class performance in lubricity, durability, and particulates. Our coatings give you a choice to cure the coatings using either Thermal heat or Ultraviolet (UV) light. The following tests show the results of a series of tests that the Biocoat Research & Development team completed to test the lubricity and durability of HYDAK® UV on metal guidewires to see how our coatings perform compared to a polymer jacket and a competitive hydrophilic coating.

The Biocoat R&D team tested our HYDAK® UV coating applied to a commercially available guidewire with the polymer jacket stripped versus the same guidewire with the polymer jacket. HYDAK®UV showed to provide more lubricity in both initial and repeated use.

The Biocoat R&D team tested our HYDAK® UV coating applied directly to a 0.018” nitinol wire versus a 0.016” commercially available guidewire with a tie layer and topcoat. HYDAK® UV showed to provide more lubricity in both initial and repeated use.

Our team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

The latest news, articles, and resources, sent to your inbox.