HYDROPHILIC COATING SOLUTIONS

Inner Diameter

Hydrophilic Coatings

- Hydrophilic coatings do not change the substrate properties. (stiffness and flexibility)

- Improved flexibility without the stiffness of PTFE liners

- Allows smooth passage of second shaft through sheaths or catheters

- Enables delivery of systems through tight bends

- Enhances trackability under compression

- Biocoat’s hydrophilic coating holds up to e-beam and gamma

- Faster processing times vs. ETO

- ID coating method provides a non-PFAS alternative without compromising quality or performance.

YOUR SOLUTION FOR COATING THE INNER DIAMETER OF YOUR MEDICAL DEVICE

Discover Biocoat’s newest patented innovation. A PFAS-free inner diameter coating which offers an alternative to PFAS materials while enhancing the overall device effectiveness.

This coating technology is characterized by exceptional lubricity, which allows medical devices to navigate through narrow or tortuous pathways in the body with minimal resistance. This reduces the potential for tissue damage and can improve efficiency. The lubricious nature of the coating, combined with its durability, ensures that devices maintain their performance throughout the procedures.

In addition to its lubricity, Biocoat’s non-PFAS coating offers impressive flexibility. This is particularly beneficial for devices such as catheters, which require both flexibility and durability to perform effectively in challenging anatomical environments. The coating can withstand the rigors of multiple flexions and stresses, ensuring the longevity of the device.

Maximum Efficiency With Best-In-Class Performance

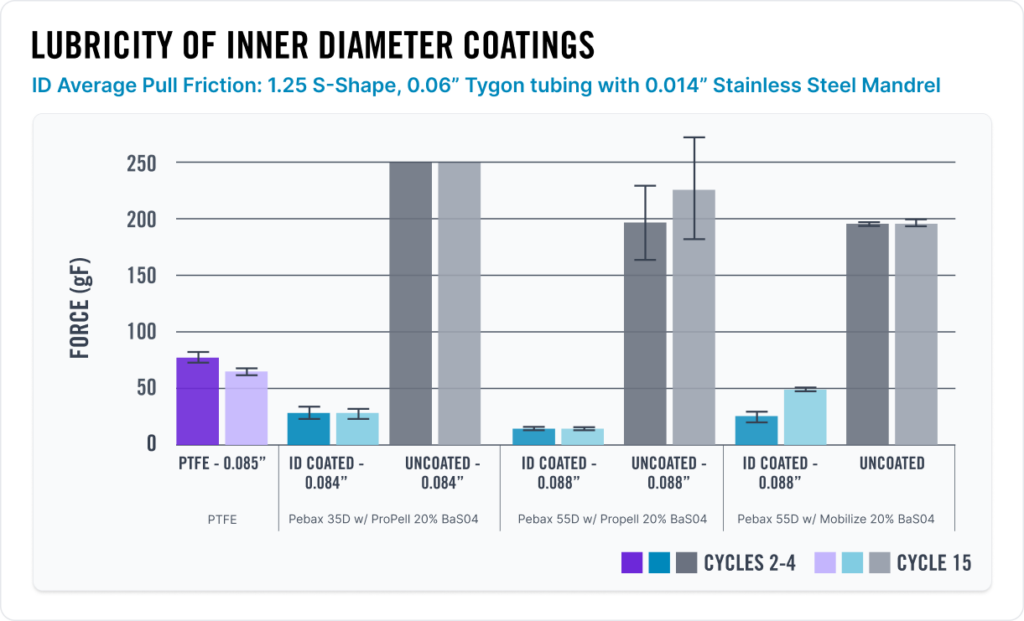

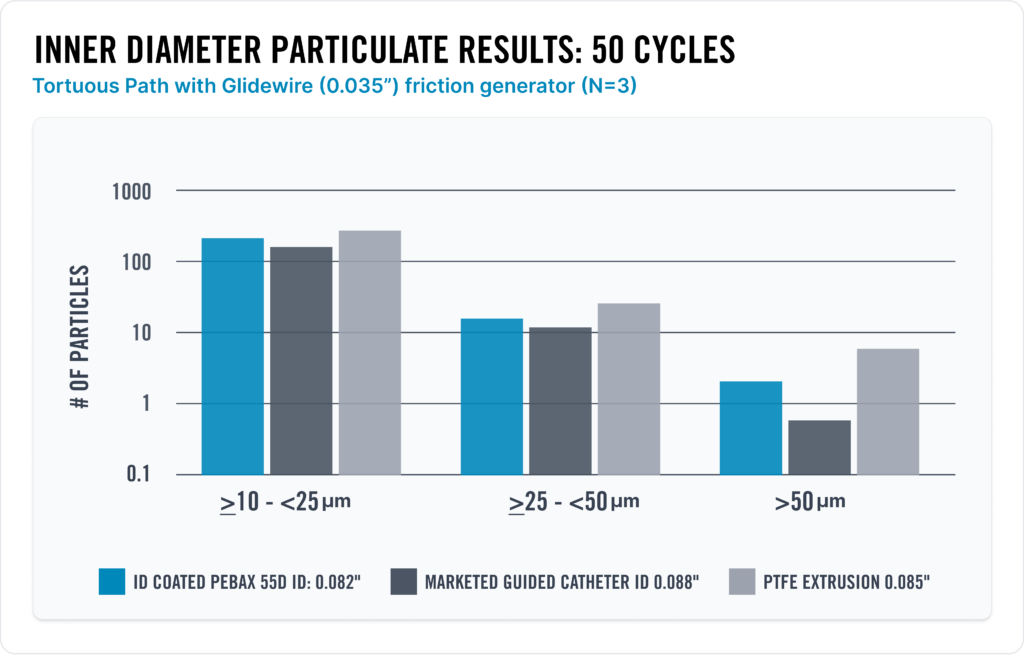

At Biocoat, our HYDAK® coatings offer best-in-class performance in lubricity, durability, and particulates. The following tests show the results of a series of tests that the Biocoat Research & Development team completed to test the lubricity and durability of HYDAK® Thermal on the inner diameter to see how our coatings perform compared to a PTFE liner.

HYDAK® Thermal coating was tested on various Pebax® catheter tubing sizes, comparing it to uncoated Pebax® tubing and a PTFE liner. HYDAK Thermal demonstrated superior lubricity in both initial and repeated use.

HYDAK® Thermal coating was tested on the inner diameter of Pebax® 55D catheter tubing, comparing it to a commercially available guide catheter and PTFE extrusion. HYDAK Thermal demonstrated comparable particulate counts.

Common Devices

Interested in an Inner Diameter Hydrophilic Coating Solutions for your Devices?

Our team of engineers and coating experts would be glad to have a discussion about your project and its requirements.

A standard engagement with Biocoat follows:

-

Contract Coating ServicesBy utilizing Biocoat’s Contract Coating Services offering, you are free to focus on device innovation, design, and assembly, without the need to incorporate complex and coating processes into your manufacturing lines. Our best-in-class customer service, world class coating equipment, process controls, and rapid turnaround times are a commonly selected option to give you peace of mind that your device’s hydrophilic coating application is taking care of by experts.

-

Reagent FulfillmentIf you plan to coat the devices at your facility, we support you through the same best-in-class customer support and world-class coating manufacturing operations. We’re committed to delivering your coating materials on time, and as expected, every time. Our online ordering system is backed by a live Customer Support team, who are eager to assist with any questions or support you may require.