HYDROPHILIC COATING SERVICES

High-Touch Hydrophilic Coating Services From Discovery Through Development

As leading experts in the development, production and application of hydrophilic coatings, we provide best-in-class service to support you at every step.

COATING APPLICATION DEVELOPMENT

We research, apply, and test our coatings on your device to ensure maximum performance.

CONTRACT COATING SERVICES

Comprehensive solutions designed to ensure that your products will be expertly coated

SERVICES WE OFFER

Throughout Your Project Development

Quickly determine how your device performs with our high-performing medical device coatings

We work with you to design a coating that best matches your device’s requirements

Work with our coating experts to maximize coating performance and support the launch of your project

OUR SERVICES PROCESS

The Journey to Success

Project Review

This initial review is to determine if there is a fit between your project’s unique specifications and our HYDAK coatings. If both parties agree on moving forward, we start the feasibility testing process.

Feasibility Testing

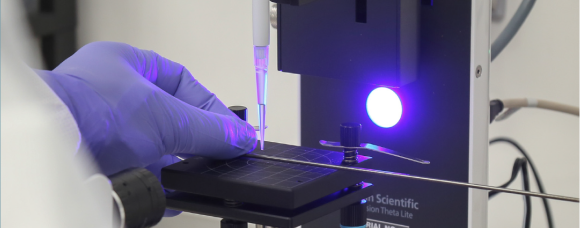

During the feasibility testing process, we ask for approximately 10 samples for us to perform a high-level coating test. Once the coating is complete, we test the sample material for lubricity and durability, and then perform a dye test to ensure the coating adhered as expected. In conjunction with the testing performance results, we send some coated materials for you to test at your own facility.

Coating Development & Optimization

Collaboration is vital during this stage, as we are working together to develop the coating that best matches your device. Planning for validation, regulatory submission and for large scale coating application via either our Contract Coating Services unit or fulfillment at your production facility.

Contract Coating Services

Our comprehensive Contract Coating Services for medical devices is specifically designed to ensure that your products will be expertly coated for maximum safety, maneuverability and patient comfort. Our best-in-class customer service, ability to cure using UV or Thermal and rapid turnaround times are a perfect fit to support your outsourced manufacturing process.

Reagent Fulfillment

If your plan is to coat the devices at your facility, we support you through flawless customer support to ensure that you receive your materials on-time and as expected every time. Our Customer Service team is always available to assist with any questions or support that you may require.

Coating Equipment

To support your in-house coating efforts, we offer fully automated and semi-automated equipment options for both UV and Thermal curing. Our equipment is a perfect compliment for your in-house manufacturing process.Learn More +

Biocoat rapid hydrophilic coating testing service can assist OEMs in the measurement of coating performance in comparison to existing in-house coatings or to determine how your project performs with the industry’s highest-performing options.

Start-up companies are often at the forefront of new and exciting development programs, and Biocoat has over 30 years of experience supporting these projects. Our engineers are available to provide detailed support during the entire medical coating testing process, and can help you achieve a successful result.

Are you looking to test your project’s performance with our industry-leading HYDAK coatings?

Do you need to ensure that your devices are expertly coated in preparation for patient use?

Our best-in-class service offering is specifically designed to assist in the testing and maximization of hydrophilic coatings on intravenous medical devices. Our custom, lubricious, abrasion resistant and biocompatible hydrophilic coatings can be applied to a wide range of polymeric and metallic substrates using either a thermal or UV curing technology.

- Substrate Materials

- Device Usage

- Learn more about our Contract Coating Services in this video.

- Learn more about our UV Contract Coating Services in this video.

OUR SERVICES PROCESS

The Journey to Success

Project Review

Our Application Engineering Team facilitates an initial review to determine fit between your project’s unique specifications and our HYDAK hydrophilic coatings. Once confirmed, our team quickly moves to the Feasibility stage.

Feasibility Testing

An Application Engineer is assigned to your program, who then initiates the feasibility testing phase. A small number of samples will be requested to be used for initial high-level coating trials. The samples are evaluated for coating readiness (cleanliness), cleaned as needed, and then coated with our initial Hydak coating selection and process. The coated samples are then tested for lubricity, durability and coverage. In conjunction with the testing performance results, coated samples are returned to the customer for a parallel assessment. Speed is critical during all phases of product development, and our resources are positioned to meet your lead-time needs with a standard short lead-time and expedite options as quick as 24 hours.

Coating Development & Optimization

Collaboration is vital during this stage, as we are working together to finalize the coating selection and application process that best suites the device’s performance requirements. Planning for validation, regulatory submission (as required), transfer to production, and scaling to match expected market demand, also occurs during this critical phase.

Contract Coating Services

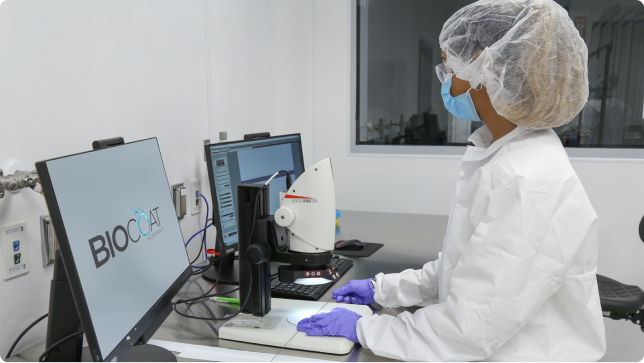

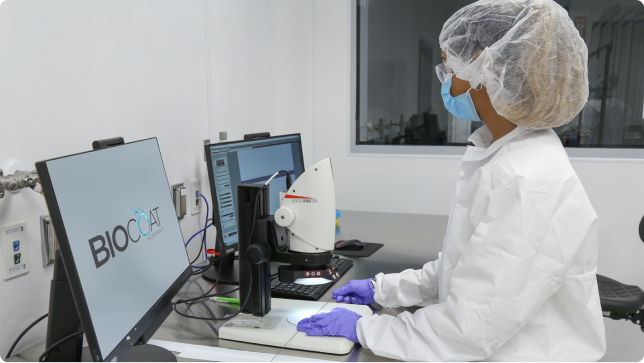

By utilizing Biocoat’s Contract Coating Services offering, you are free to focus on device innovation, design, and assembly, without the need to incorporate complex and coating processes into your manufacturing lines. Our best-in-class customer service, world class coating equipment, process controls, and rapid turnaround times are a commonly selected option to give you peace of mind that your device’s hydrophilic coating application is taking care of by experts.

Reagent Fulfillment

If you plan to coat the devices at your facility, we support you through the same best-in-class customer support and world-class coating manufacturing operations. We’re committed to delivering your coating materials on time, and as expected, every time. Our online ordering system is backed by a live Customer Support team, who are eager to assist with any questions or support you may require.

Contract Coating Services

Do you need to ensure that your devices are expertly coated in preparation for patient use?

- Our turnkey Contract Coating Services (available in both UV and Thermal Cure) are specifically designed to ensure that your medical devices and products will be expertly coated for maximum safety, maneuverability, and patient comfort.

Contract Coating Benefits

Our Contract Coating Services Solution Offers:- Seamless application of our industry-leading hydrophilic formula on your device Ability to cure the coating using either Thermal heat or UV light

- Act as a reliable alternative to existing in-house facilities

- A stable and repeatable application process

- Customizable fulfillment to support your product’s unique needs

- Rapid and efficient turnaround times to meet your production schedule

Contract Coating